Nanoengineered electrospun fibres and fibre reinforced PTMC composite

-

1

Queen Mary University of London, School of Engineering and Materials Science, United Kingdom

-

2

University of Twente, Department of Biomaterials Science and Technology, Netherlands

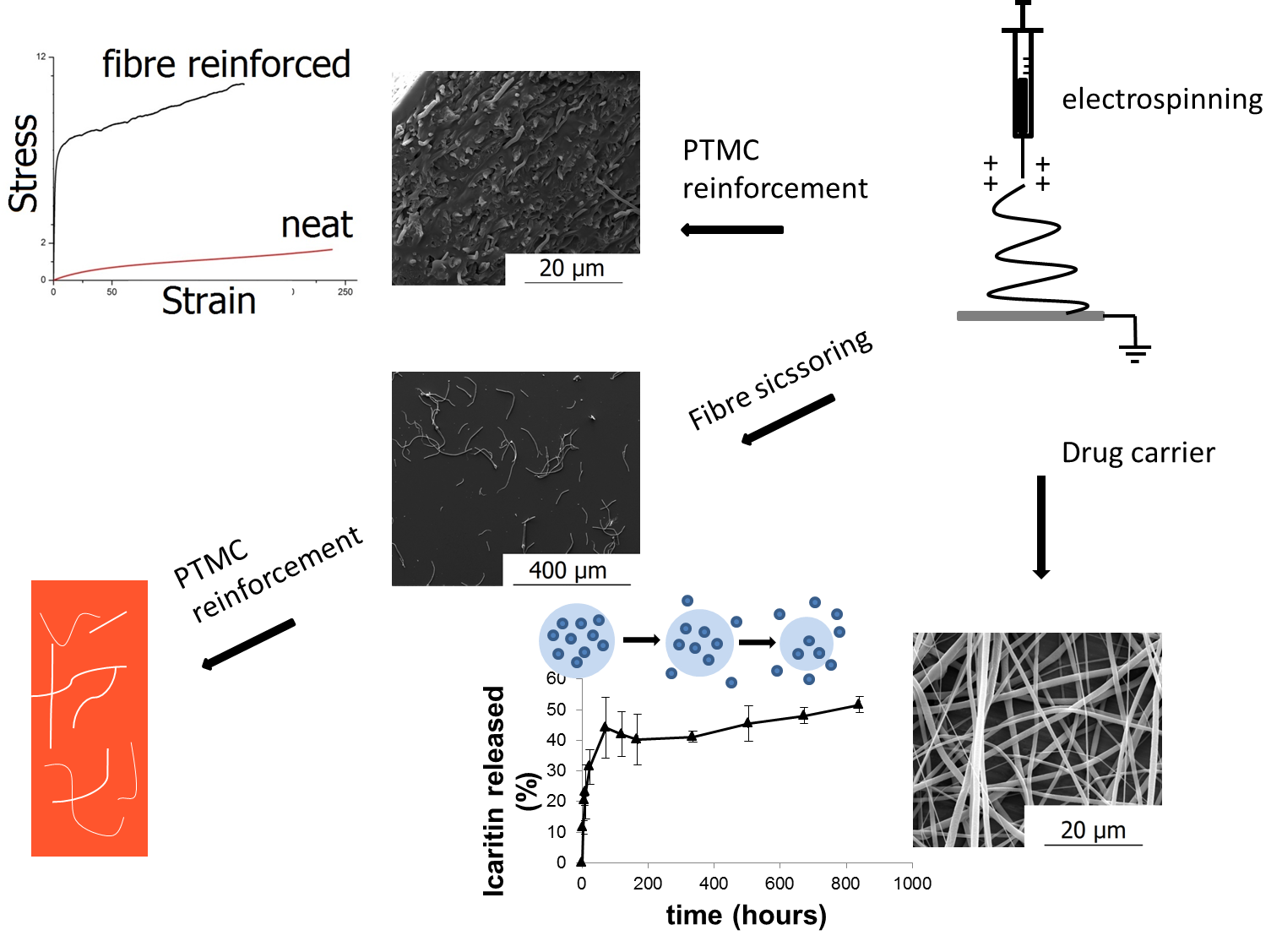

Poly (trimethylene carbonate) (PTMC) is a biodegradable elastomeric material with potential application for tissue engineering. However it has been restricted due to its high compliance and poor mechanical properties. Recently it was reported that crosslink of methacrylate-ended PTMC macromer was able to produce stronger and tougher material [1]. Incorporation of nanoparticles (e.g. calcium phosphate) could further enhance the mechanical properties of PTMC, but the weak bonding between filler and matrix could possibly lead to materials failure especially after long incubation times [2]. The large surface area and aspect ratio of electrospun fibres also makes them attractive fillers for polymer-polymer biocomposites and offer additional opportunities for drug release [3]. Therefore the combination of electrospun fibres and PTMC could not only improve the performance of PTMC but also create novel drug release systems for tissue engineering applications.

In this project polylactide (PLA), a well-known biodegradable polymer widely used in the food industry (packaging) and biomedical applications [4], was electrospun into submicron fibres and incorporated into three-armed methacrylate-ended PTMC macromer resins. The resin was then exposed to UV to crosslink and formed PTMC/fibre composites. As original electrospun fibres were difficult to process when preparing composites, short fibres were used in addition to long fibres to enhance the mechanical properties of PTMC. The short PLA fibres were achieved by either sonication or vigorously stirring as-spun fibres in organic media and loaded into PTMC by mechanical mixing. The morphology of fibres and PTMC-fibre interfacial interaction was characterized using SEM. Most fibres have smooth morphology with no defects observed. The sonication and solvent assisted fibre cutting system successfully chopped long fibres into short ones, simplifying composite preparing procedures. The highly porous electrospun fibre network was filled with PTMC matrix. Fibres and PTMC were strongly bound, as evidenced by the absence of fibre pull-out during composite fracture. Instron tensile testing allowed to characterise the mechanical properties of PTMC/fibre composites. The modulus, strength and toughness were significantly improved with the incorporation of electrospun fibres. Moreover, the drug icaritin was loaded into electrospun fibres during the electrospinning process. It was reported that icaritin could direct differentiation and proliferation of osteoblasts [5]. Icaritin released from electrospun fibres was monitored using HPLC. A relatively quick icaritin release (but not burst release) was seen at the beginning; a slow and continuous release profile was then detected. The controlled icaritin release behaviour of electrospun fibres makes it suitable as a drug carrier for biomedical applications.

The Rapidos project

References:

[1] Schüller-Ravoo S, Feijen J, Grijpma DW. Flexible, elastic and tear-resistant networks prepared by photo-crosslinking poly (trimethylene carbonate) macromers. Acta Biomaterialia 2012. 8 (10): 3576-3585.

[2] Lin S et al. Electrospun nanofiber reinforced and toughened composites through in situ nano-interface formation. Composite Science and Technology 2008. 68 (15-16): 3322-3329.

[3] Zheng J et al. Biodegradable electrospun fibers for drug delivery. Journal of Controlled Release 2003. 92 (3): 227-231.

[4] Jamshidian M et al. Poly-Lactic acid: production, application, nanocomposites, and release studies. Comprehensive Reviews in Food Science and Food Safety 2010. 9 (5): 552-571.

[5] Chen SH et al. PLGA/TCP composite scaffold incorporation bioactive phytomolecule icaritin for enhancement of bone defect repair in rabbits. Acta Biomaterialia 2013. 9 (5): 6711-6722.

Keywords:

Drug delivery,

nanofiber,

composite,

mechanical property

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Composites: polymeric, ceramic and metallic

Citation:

Zhang

X,

Geven

M,

Gautrot

J,

Grijpma

D and

Peijs

T

(2016). Nanoengineered electrospun fibres and fibre reinforced PTMC composite.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01293

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Xi Zhang, Queen Mary University of London, School of Engineering and Materials Science, London, United Kingdom, Email1

Dr. Mike Geven, University of Twente, Department of Biomaterials Science and Technology, Enschede, Netherlands, m.a.geven@utwente.nl

Dr. Julien Gautrot, Queen Mary University of London, School of Engineering and Materials Science, London, United Kingdom, j.gautrot@qmul.ac.uk

Dr. Dirk Grijpma, University of Twente, Department of Biomaterials Science and Technology, Enschede, Netherlands, d.w.grijpma@utwente.nl