Material and scaffold design and development for intervertebral disc tissue engineering and regeneration

-

1

Loughborough University, Wolfson School of Mechanical and Manufacturing Engineering, United Kingdom

-

2

Universita' di Milano, Dipartimento di Fisica, Italy

-

3

Fondazione Filarete, Italy

Introduction: The nucleus pulposus (NP) and annulus fibrosus (AF) of the intervertebral disc (IVD) are more subject to degeneration and rupture with the progress of aging. Our previous study have proved the feasibly of applying photocurable, biodegradable polymer hydrogel for nucleus pulposus regeneration[1]. In the current study material and scaffold design and development of injectable polymer hydrogel together with electrospun polycaprolactone (PCL) scaffolds was investigated with the intention of demonstration the feasibility of replication of the anisotropic structure of AF and the confined compression of IVD biomechanics.

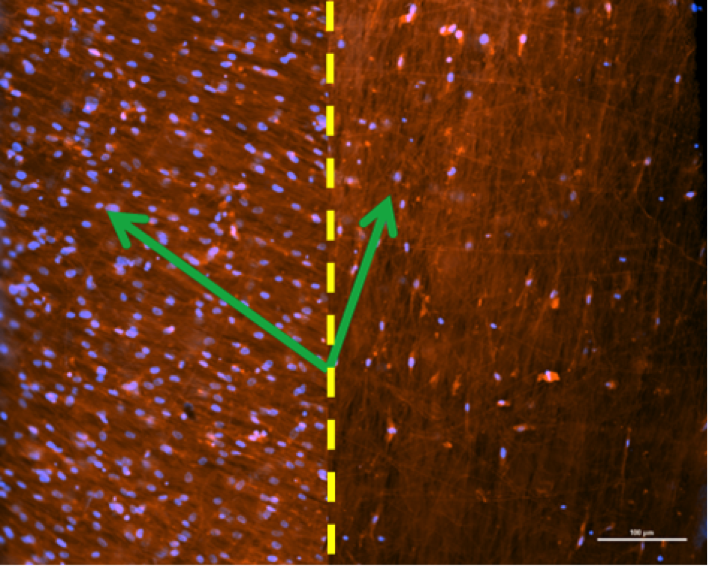

Method: Electrospun PCL laminate with sub-micron fibres arranged in aligned manners were prepared and their anisotropic mechanical property were further characterised at various stretching angle. Biocompatibility of electrospun layers with human mesenchymal stem cells (hMSCs) was carried out to assess cell adhesion, viability and orientation with the configuration of single laminate. Viability of cells at the interface of stacked angle-ply laminates with/without exposure to confined compression was also assess using BOSE bioreactor.

Results: Aligned PCL nano-fibers can be applied as a template to guide the alignment of hMSCs.

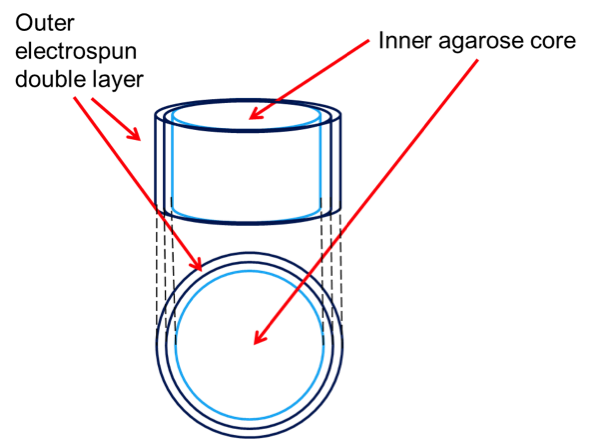

Mechanical properties of the electrospun PCL laminates dependence on the combination of fibre orientation and environmental conditions. hMSCs cultured on mono-, double- and multi-layers showed a strong influence of laminate scaffold features and configuration on cell morphology and viability. Cells showed good integration with 3-dimensionally angle-ply arranged electrospun PCL layers, and migration capability. Cell viability was found to be dependent on matrix thickness and, to a less extent, fibre diameter. A reliable methodology to mount cellularised double layers around agarose cores, in order to resemble the IVD configuration, was developed and found to be adequate when subjected to compressive mechanical stimulation in the bioreactor.

Conclusion: Electrospun nano- and micro-fibres can be produced with controllable fibre size and orientation arrangement. Synergistic investigations that combine the development of novel material and scaffold design and production could be one of the most promising modular approaches for tissue engineering and regenerative medicine of IVD.

Research supported by Loughborough University graduate school PhD studentship (AF), Royal Society and FP7 SkelGen.

References:

[1] D. Kumar, I. Gerges, M. Tamplenizza, C. et.al., Acta Biomaterialia. 2014 Aug; 10(8):3463-74

Keywords:

Regenerative Medicine,

Tissue Engineering,

Biomimetic,

disc replacement

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Biomimetic materials

Citation:

Fotticchia

A,

Demirci

E,

Lenardi

C and

Liu

Y

(2016). Material and scaffold design and development for intervertebral disc tissue engineering and regeneration.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.01028

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Emrah Demirci, Loughborough University, Wolfson School of Mechanical and Manufacturing Engineering, Loughborough, United Kingdom, e.demirci@lboro.ac.uk

Dr. Cristina Lenardi, Universita' di Milano, Dipartimento di Fisica, Milan, Italy, cristina.lenardi@mi.infn.it

Dr. Yang Liu, Loughborough University, Wolfson School of Mechanical and Manufacturing Engineering, Loughborough, United Kingdom, Email1