Magnesium and its alloy have been considered as potential biodegradable implant materials for orthopedic device for it they have great biocompatibility and antibacterial property[1],[2]. One of the limitations for the usage of magnesium is its fast corrosion rate. Some researchers fabricated fluoridated hydroxyapatite (FHA, Ca5(PO4)3(OH)1-xFx) on the surface of magnesium alloy, and found FHA coating could make the alloy more stable and had better corrosion resistance[3]. However, slower corrosion rate result in less alkali, which decreased the antibacterial property[4]. We fabricated FHA-Ag on the surface of pure magnesium and discussed, both in vitro and in vivo, its corrosion behavior, and antibacterial property.

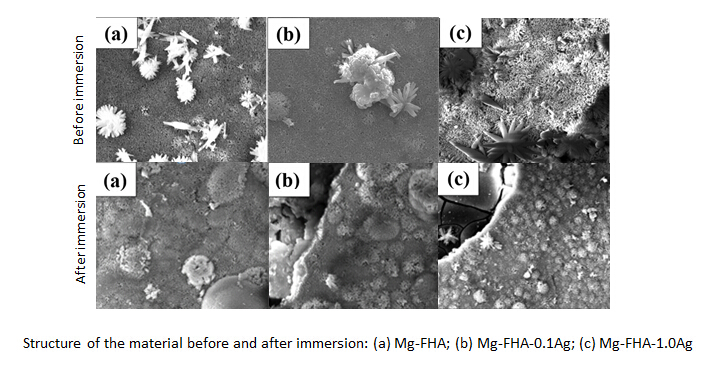

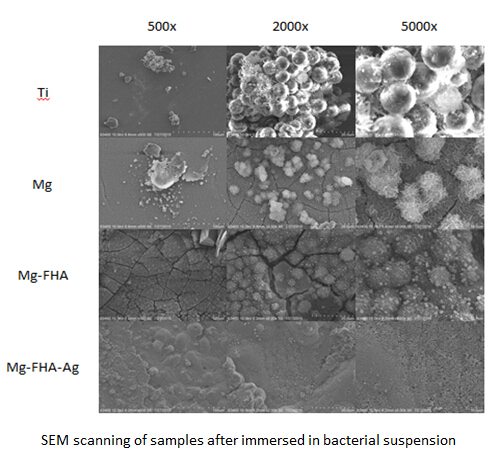

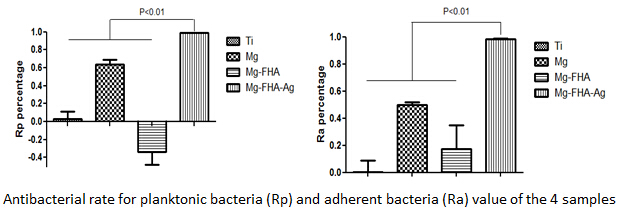

Material characteristic of Mg-FHA-Ag fabricated by different methods was tested both before and after 2 weeks of immersion in SBF, including surface morphology determined by scanning electron microscope, and percentage of elements examined by Energy Dispersive Spectrometer (EDS). Mass loss, hydrogen release, PH value, Ag release and MTT were tested to determine the corrosion rate and the cytotoxicity of the Mg-FHA-Ag. Methicillin-resistant Staphylococcus aureus was used to measure the antibacterial property of Mg-FHA-Ag. In vitro, the anti-planktonic bacteria rate (Rp) and anti-adherent bacteria rate (Ra) were evaluated by the spread plate method. SEM and CLSM test were performed to evaluate the quantity and activity of the bacteria. In vivo, the antibacterial property of Mg-FHA-Ag was tested in early acute osteomyelitis model. Micro-CT and histological test were performed to assess bacterial contamination. And the biosecurity of Mg-FHA-Ag was tested by histological analyzing different organs.

The result of SEM showed two different structures of FHA-Ag, compact nano rod-like structure at the bottom and branching or broccoli-like structure on the top. The structure remained the same after immersion. The result of mass loss, hydrogen release and PH value test suggested that Mg-FHA-Ag has great degradation resistance compared to pure magnesium. EDS showed the amount of Ag decreased sharply after the immersion, which was further proved by Ag releasing test that “explosive releasing” appeared in the first 4 days of immersion. However, MTT test illustrated no cytotoxicity during the “explosive releasing” period. Mg-FHA-Ag revealed great Rp and Ra compared to pure magnesium, and the SEM and CLSM tests found dramatically decrease of quantity and activity of the bacteria on the surface of Mg-FHA-Ag. In according with in vitro test, the result of micro-CT and histological test also demonstrated great antibacterial property and corrosion resistance of Mg-FHA-Ag. Histological analysis showed no Ag deposition in different organs.

The results suggested that FHA-Ag coating effectively enhanced the corrosion resistance, and at the same time, it has better antibacterial property than magnesium.

References:

[1] Staiger, M.P., et al., Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials, 2006. 27(9): p. 1728-34.

[2] Witte, F., The history of biodegradable magnesium implants: a review. Acta Biomater, 2010. 6(5): p. 1680-92.

[3] Song, Y., et al., Electrodeposition of Ca-P coatings on biodegradable Mg alloy: in vitro biomineralization behavior. Acta Biomater, 2010. 6(5): p. 1736-42

[4] Qin H, E.A., Anti-biofilm properties of magnesium metal via alkaline pH. 2015. p. 21434-21444