Introduction: Hydroxyapatite (HAP), having a chemical formula of Ca10(PO4)6(OH)2, is the major component of tooth enamel and bone mineral. Because of its excellent biocompatibility and bioactivity, HAP was extensively used in medical field [1],[2]. To obtain complex structure to face bone repairmen and cell growth, additive manufacturing of HAP has been investigated by many researchers [3]-[6]. However, binders are always used in the previous studies[3]-[6], which will decrease the component strength and bioactivity, limiting its application. Therefore, the direct selective laser melting of HAP without using binder was investigated to improve its strength to expand its application.

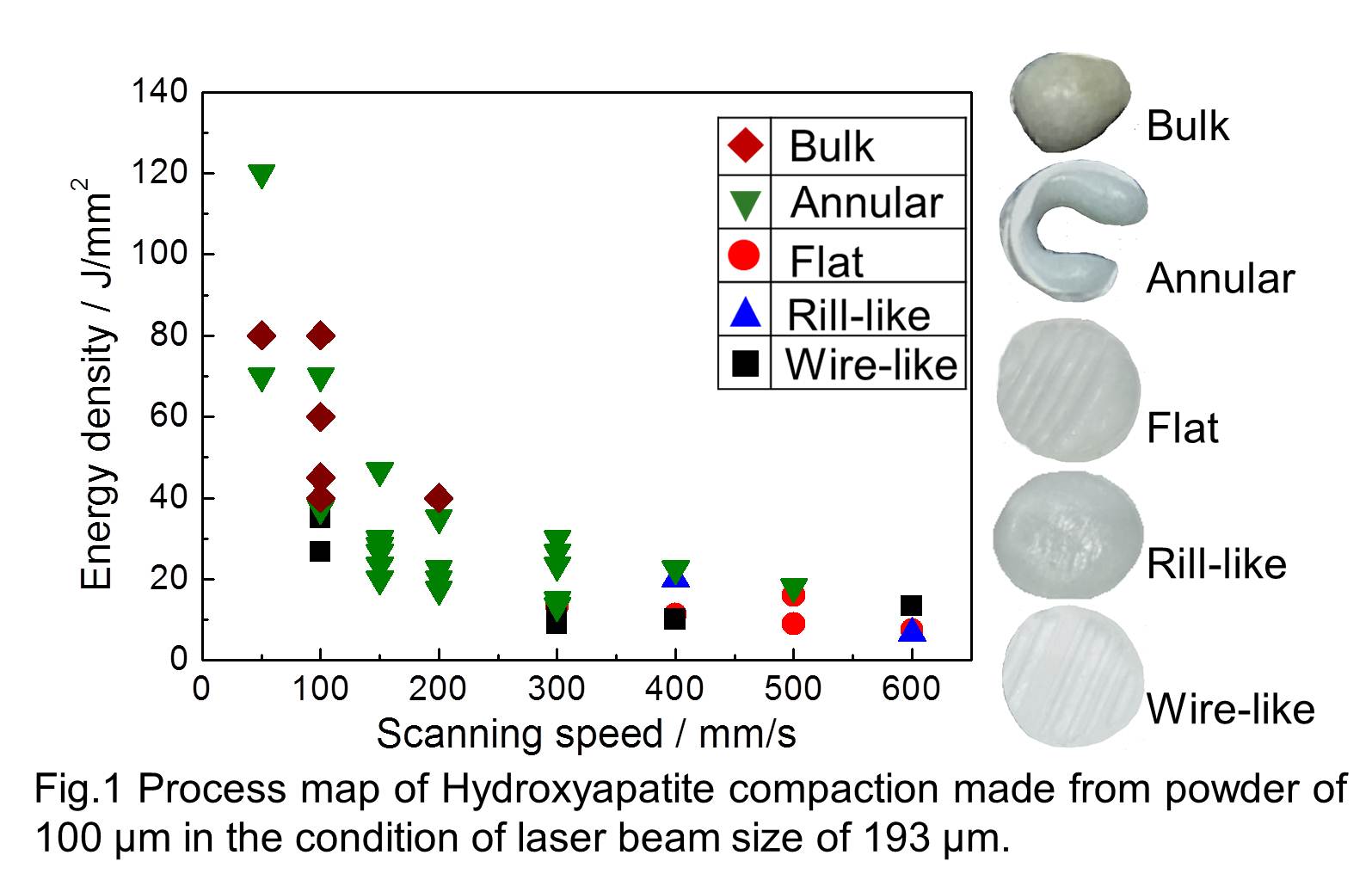

Experimental: HAP powders with average size of 30 μm and 100 μm were directly scanned by laser beam in the state of powder and compaction. The sintering property was studied in one layer process. To disperse the beam energy to reduce the powder decomposition, the beam size was increased from 88 μm to 193 μm. The snake-like pattern was used for beam scanning. The surface morphology and internal microstructure were investigated by Scanning electron microscope (SEM), and phase composition was analyzed by XRD and Fourier transform infrared spectroscopy (FTIR). Vickers hardness was tested to evaluate the mechanical property of sintered HAP powders.

Results and Discussion: The decomposition of HA powders often occurs prior to melting [1],[2],[7],[8], which makes the powder size decrease largely when melting begins, so that it is very difficult for the sintering of the powders. The consolidation of powders by full melting was available when the powders were compressed into a block in advance of selective laser melting. The melting of the compressed powder block can become easily by increasing beam size and decreasing the powder size. With increasing the energy density, majority of the HA in the solidified part decomposed into calcium phosphate, including α-tricalcium phosphate (α-TCP), β-tricalcium phosphate (β-TCP), tetracalcium phosphate (TTCP) and some amorphous phases. Because of the high residual stress caused by the rapid cooling, there was numerical crack on the solidified surface.

Conclusions: The compression of HAP powders was necessary to reach the direct consolidation purpose. Larger powder size and beam size contributed to reduce HAP decomposition to increase the consolidation ability. The sintering part with major composition of HAP can be obtained by selective laser melting.

References:

[1] G. Muralithran, S.Ramesh, The effects of sintering temperature on the properties of hydroxyapatite, Ceramics International 26 (2000) 221-230.

[2] S. Ramesh, K.L. Aw, R. Tolouei, M. Amiriyan, C.Y. Tan, M. Hamdi, J. Purbolaksono, M.A. Hassan, W. D. Teng, Sintering properties of hydroxyapatite powders prepared using different methods, Ceramics International 39 (2013) 111-119

[3] L. Hao, M.M. Savalani, Y. Zhang, K.E. Tanner, R.J. Heath, R.A. Harris, Characterization of selective laser-sintered hydroxyapatite-based biocomposite structures for bone replacement, Proc. R. Soc. A 463 (2007) 1857-1869.

[4] K. Xiao, K.W. Dalgarno, D.J. Wood, R.D. Goodridge, C. Ohtsuki, Indirect selective laser sintering of apatite-wollostonite glass-ceramic, Proc. IMechE 222 (2008) 1107-1114.

[5] F. Cruz, Fabrication of HA/PLLA composite scaffolds for bone tissue engineering using additive manufacturing technologies, Biopolymers, Magdy Elnashar (Ed.) (2010) 227-242.

[6] S. Eosoly, D. Brabazon, S. Lohfeld, L. Looney, Selective laser sintering of hydroxyapatite/poly-ε-caprolactone scaffolds, Acta Biomaterialia 6 (2010) 2511-2517.

[7] Y.Z. Yang, K.H. Kim, C.M. Agrawal, J.L. Ong, Interaction of hydroxyapatite-titanium at elevated temperature in vacuum enviroment, Biomaterials 25 (2004) 2927-2932

[8] A. Arifin , A.B. Sulong , N. Muhamad, J. Syarif , M.I. Ramli , Material processing of hydroxyapatite and titanium alloy (HA/Ti) composite as implant materials using powder metallurgy: A review, Materials and design 55 (2014) 165-175.