Statement of Purpose: Vascular stent functionality requires the ability to resist elastic outward recoil and overall deformation during its intended lifetime. Production of biodegradable stent materials includes melt extrusion, and in some cases radial expansion, of high stiffness and long lasting polymers. Poly-Med, Inc. has developed a long lasting high lactide based material, Lactoprene® 8812, capable of being processed into stent materials with increased toughness and limited acidic degradation by-products due to incorporation of carbonate groups compared to standard high lactide based materials. One of the challenges when creating a biodegradable stent is creating a structure that has the necessary stiffness to withstand physiological forces, but with sufficiently thin-walls to allow adequate vascular flow. In this work the effects of radial expansion on extruded Lactoprene® 8812 stent materials was determined and compared to extruded stents. The results indicate that radial expanded stents perform near equivalent to extruded stents based on mechanical and crystallinity analysis.

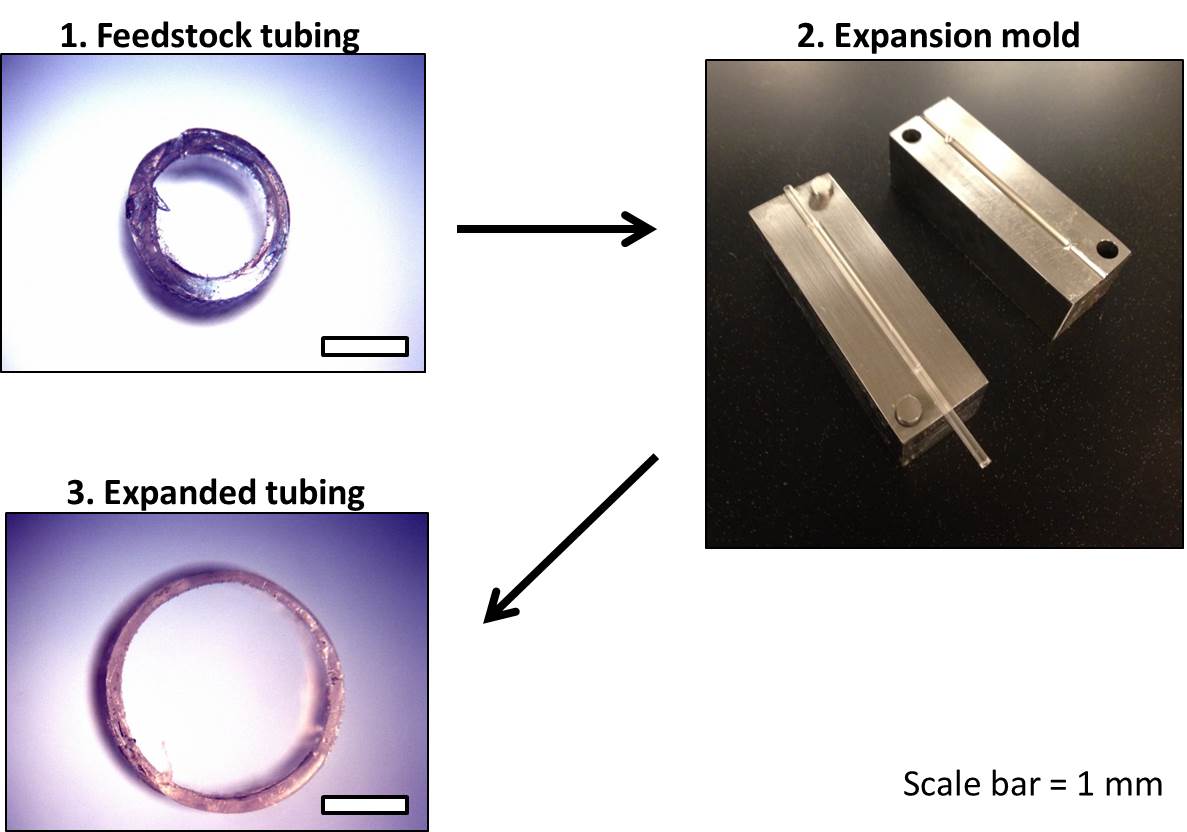

Methods: Lactoprene® 8812 polymer was synthesized and extruded into “feedstock” tubing to be radially expanded. Feedstock tubing with an outer diameter of 2.0 mm was placed in a custom mold, heated, and pressurized with nitrogen gas to expand the tube to ~3.0 mm (Figure 1). In order to determine the benefits of the radial expansion process, stents with similar dimensions were created for comparison using a conventional extrusion process. Stents were evaluated for dimensions, mechanics, and crystallinity via differential scanning calorimetry measurement.

Results: Lactoprene® 8812 was successfully formed into stent prototypes using both radial expansion (Figure 1) and conventional extrusion.

Figure 1: Schematic of radial expansion process for Lactoprene® 8812 stents.

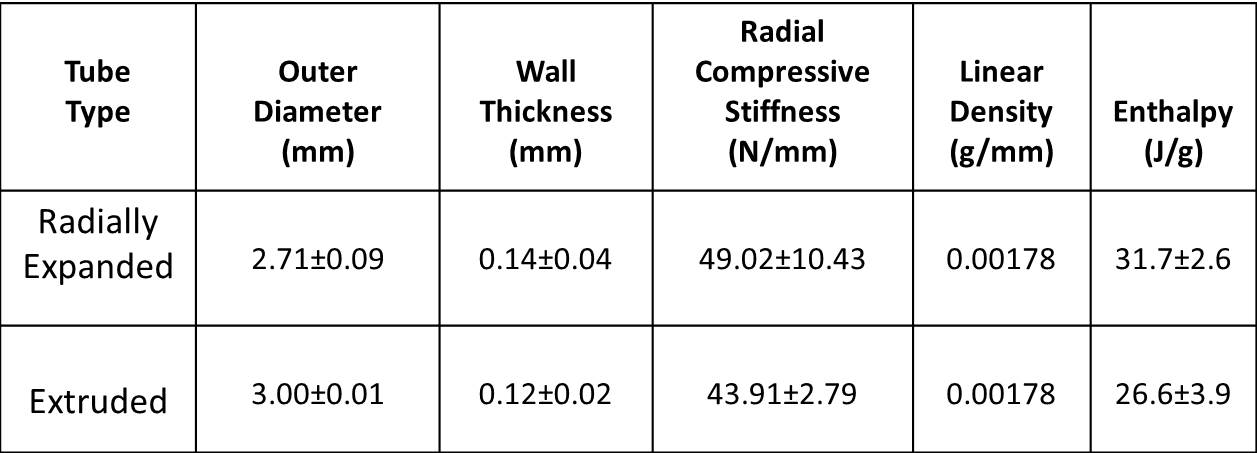

Stent prototypes were able to be expanded to approximately 1.4x their original diameter. Radially expanded stents displayed slight increases in overall mean compressive stiffness and crystallinity (via differential scanning calorimetry measurement), though neither were statistically significant when compared to values for conventionally extruded stents (Table I).

Table I: Properties for extruded and radially expanded Lactoprene® 8812 stents. Expanded and extruded tubing are statistically identical in regards to compressive stiffness, linear density, and enthalpy.

Conclusions: The results demonstrate that radial expansion does not substantially increase the stiffness or crystallinity of Lactoprene® 8812. Our findings indicate that the conventional extrusion of Lactoprene® 8812 is able to produce stent materials of similar properties without the necessity for radial expansion.