Introduction: It’s essential that the hydrogel carrier systems for drug and cell delivery be made in mild conditions quickly enough to prevent excessive loss of the drugs and cells they carry. Alginate solution can quickly form hydrogel in the presence calcium ions but the hydrogel is highly hydrophilic and degrades quickly in the presence of monovalent ions. Chitosan hydrogel is more hydrophobic and degrades more slowly compared to alginate. However, harmful chemicals are used in the process of making chitosan hydrogel and prevent chitosan from being used to encapsulate living cells.

The two materials were combined to make a better cell/drug delivery tissue scaffold. Alginate hydrogel fibers containing bone cells and diclofenac, an anti-inflammatory drug, were constructed into 3D scaffolds and coated with a layer of chitosan hydrogel. We hypothesized that the alginate hydrogel could shield the embedded cells from the acid/base used during the chitosan coating processes. The chitosan coating was then expected to better preserve diclofenac during the scaffold making and to slow down diclofenac release during cell culture.

Materials and Methods: The scaffolds were constructed by the three-dimensional (3D) plotting apparatus. In brief, an alginate solution containing osteoblasts and diclofenac was extruded into a calcium chloride+ chitosan acetic acid solution. The alginate formed hydrogel fibers with a thin layer of chitosan coating. The fibers were built layer by layer into a 3D scaffold and quickly neutralized in NaOH before rinsing (saline, pH=7).

The cell/diclofenac-containing alginate scaffolds coated with chitosan (A/C) were co-cultured with macrophage cells in a-MEM containing lipopolysaccharide (LPS). LPS stimulates macrophages to release inflammatory species that are harmful to the cells. Diclofenac was known to inhibit macrophage cells from producing the inflammatory species. The cells and drug in 3D-printed plain alginate scaffolds (A) were used as control. The drug loading and release efficacies and the performance of the cells in the scaffolds were examined.

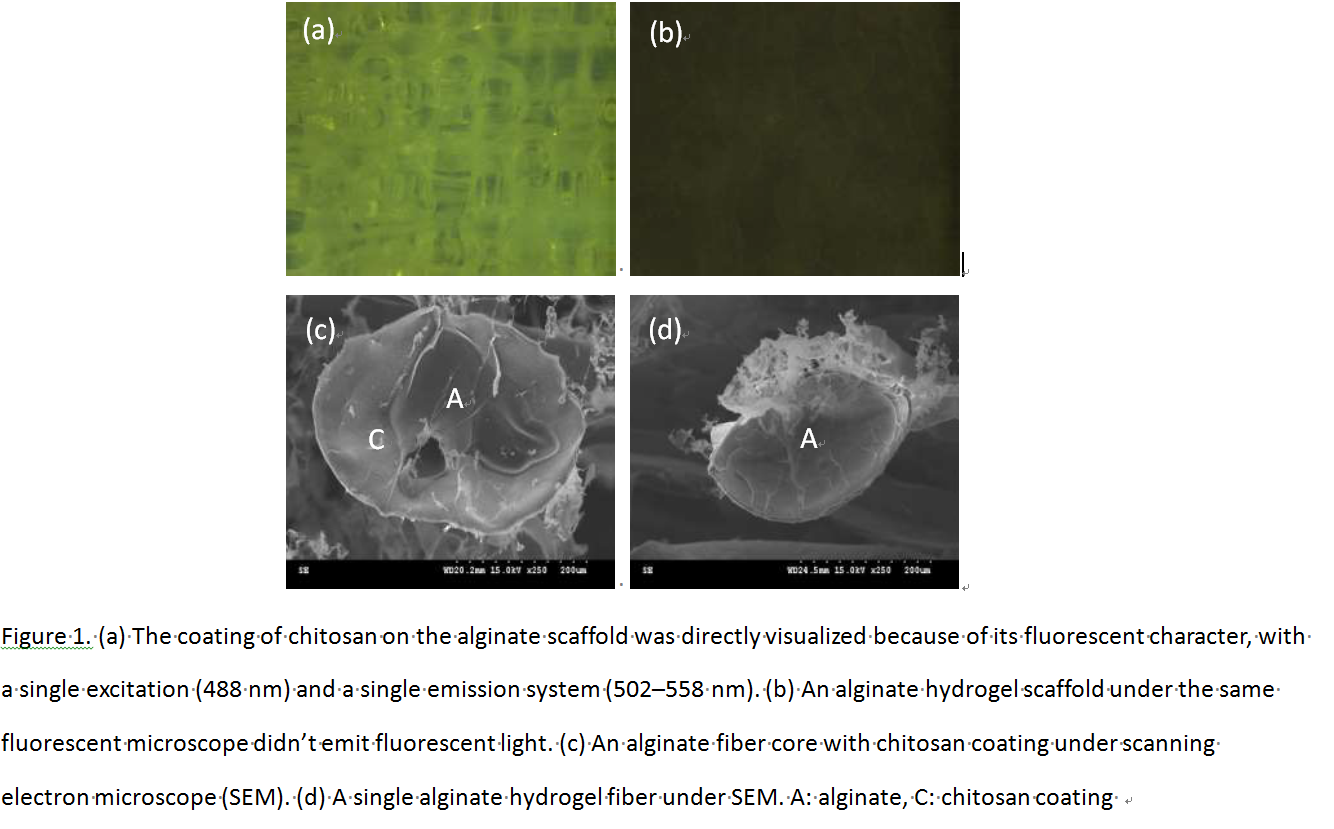

Results and Discussion: A layer of chitosan was successfully coated onto the alginate hydrogel fibers of the tissue scaffold built. Chitosan fluoresced green (Ex=488nm) and the coating could be distinguished using scanning electron microscopy (Fig1). Also the cells embedded in A/C were viable after the chitosan-coating process.

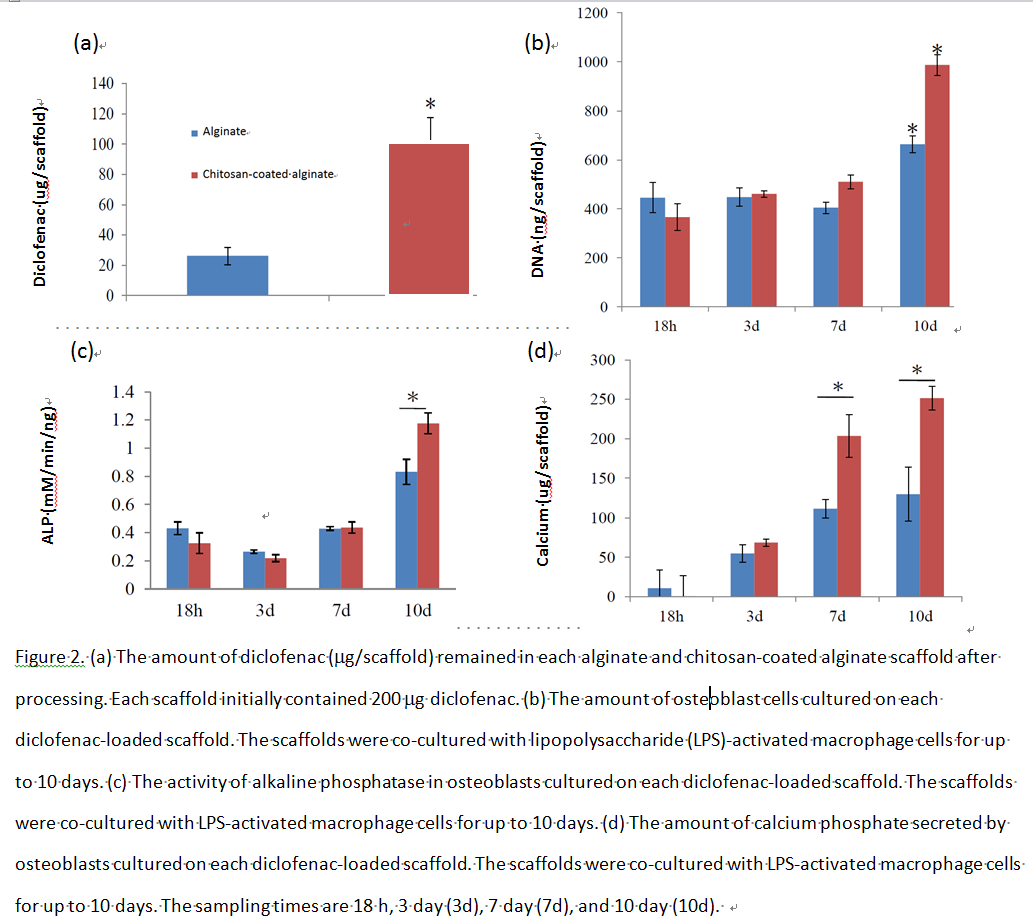

The chitosan coating was able to slow down the release of diclofenac from the alginate hydrogel. More diclofenac remained in A/C than in A after the post-processing steps were completed (Fig2).

A/C carried more diclofenac and released it in a more sustainable fashion than A. As a result the concentrations of inflammatory species from macrophages co-cultured with A/C were significantly lower than those from macrophages co-cultured with A. Osteoblasts embedded in A/C hence grew faster, had higher alkaline phosphatase activity and mineralized more extensively (Fig2).

Conclusion: A better cell/drug-containing tissue scaffold was developed by coating a layer of chitosan on the fibers of a 3D plotted alginate scaffold that contained diclofenac and cells. The cells inside the alginate hydrogel survived the harmful chemicals during chitosan coating and the coating then significantly enhanced the scaffold’s drug loading and release efficacies.

Ministry of Science and Technology grand: MOST-2221-E-027-095