β-Ti alloys with body-centered cubic (bcc) structures have attracted considerable attention as hard tissue replacements[1]. This is because they exhibit superior biocompatibility, good deformability and low Young’s modulus. In particular, it is important low Young’s modulus for the prevention of the bone degradation and absorption caused by the gap of Young’s modulus between the replacements and natural human bone[2][3], which is the so-called stress shielding. Therefore, many studies for development of the β-Ti alloys with low Young’s modulus have been carried out.

Recently, our research group investigated the elastic stiffness and elastic anisotropy of Ti-Nb-Ta-Zr alloy using its single crystal and found that a decrease in the e/a and the suppression of the athermal ω-phase precipitation are very important for the reduction of the Young’s modulus of the β-Ti alloy single crystals[4][5]. The e/a is the average number of valence electron per atom in the free atom configuration. Based on this viewpoint, we investigate the elastic stiffness and Young’s modulus of the Ti-15Mo-5Zr-3Al alloy single crystal with low e/a (= 4.1) and develop the single crystalline bone plate that has low Young’s modulus. The Ti-15Mo-5Zr-3Al alloy is one of the most promising candidate for biomaterial implant and was already an ISO-certified biomedical material.

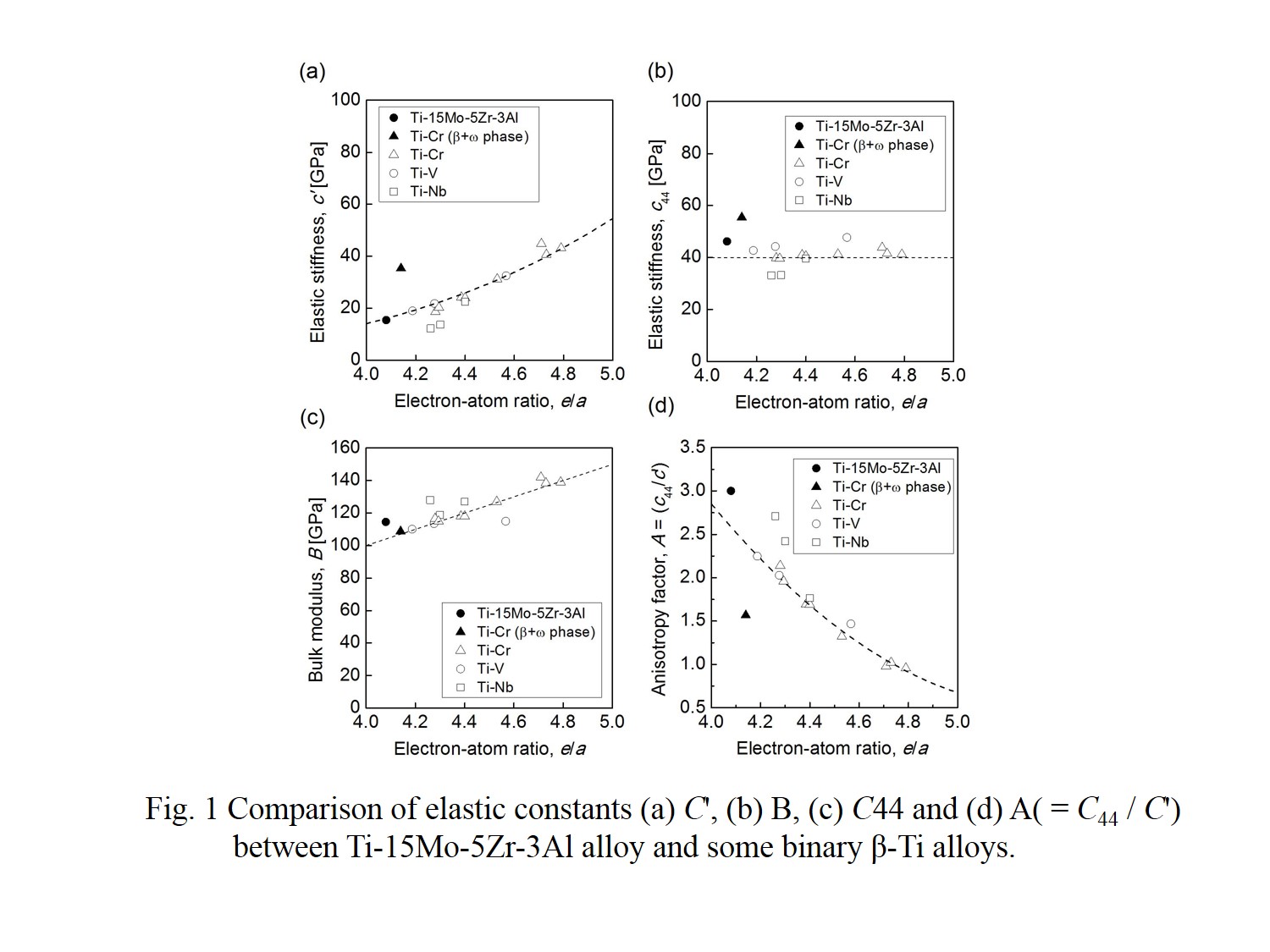

A single crystal of Ti-15Mo-5Zr-3Al alloy was grown by the optical floating zone apparatus at crystal growth rate of 2.5 mm/h under a high purity Ar gas flow. It was confirmed the suppression of the precipitation of the athermal ω-phase with relatively increasing Young’s modulus in this crystal. This single crystal also exhibited the softening of the shear modulus, C' for the {110} <1-10> shear and high value of the anisotropy factor, A (= C44/C') as shown in Fig. 1. These were related to the increase the anisotropy of the Young’s modulus.

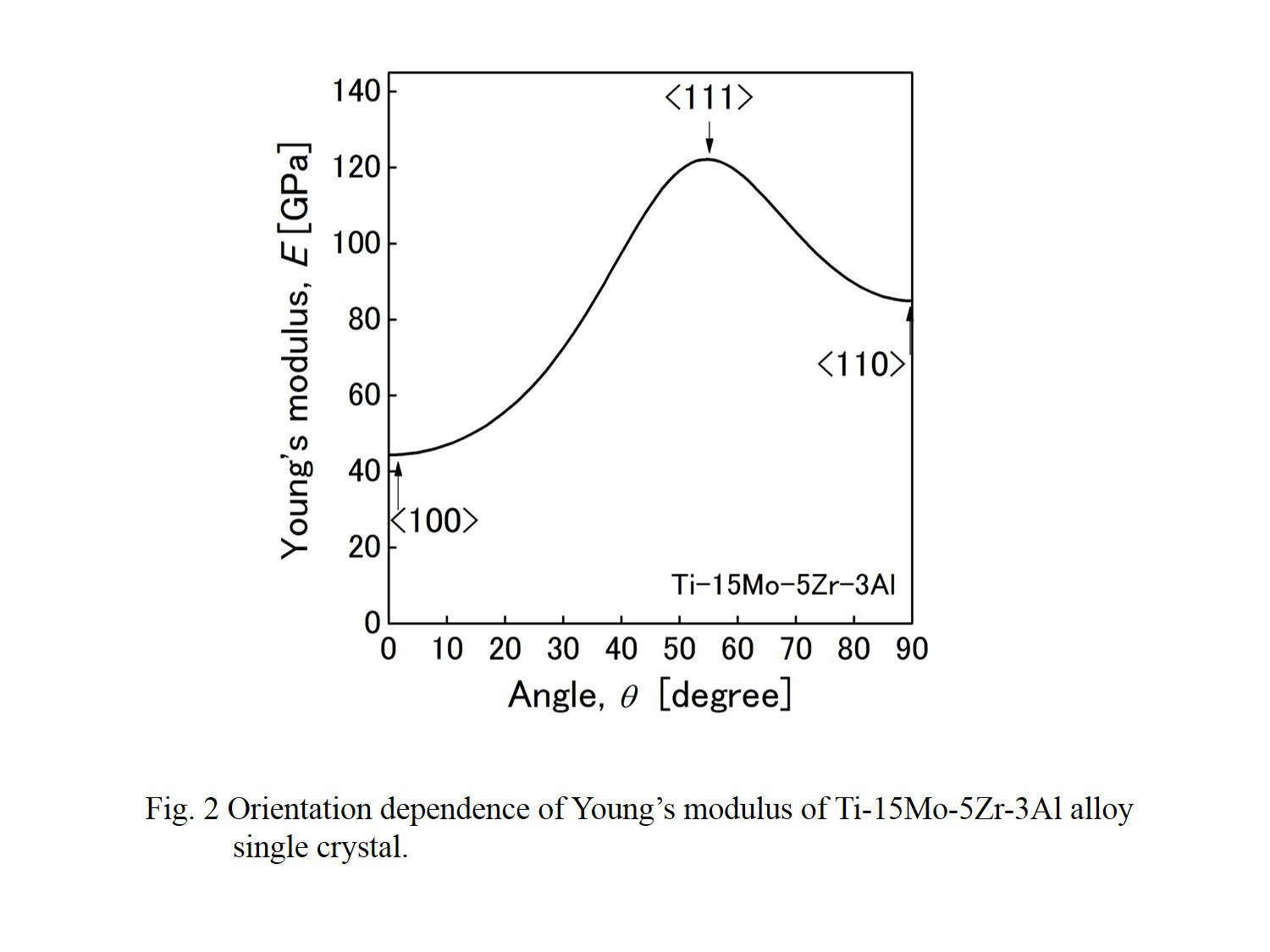

Fig. 2 shows the orientation dependence of the Young’s modulus of the Ti-15Mo-5Zr-3Al alloy crystal in directions between <100> direction to <011> direction. It can be seen that the Young’s modulus of the Ti-15Mo-5Zr-3Al alloy crystal exhibited strong anisotropy as a function of θ and the Young’s modulus along <100> direction, E100 and <111> direction, E111 are the lowest and highest of all crystallographic orientations, respectively. The value of E100 reduce to 44.4GPa[6], which is close to the value of Young’s modulus of human cortical bone (~30 GPa). From these results, we proved that a decrease in the e/a and the suppression of athermal ω-phase precipitation led to significant reduction of the E100.

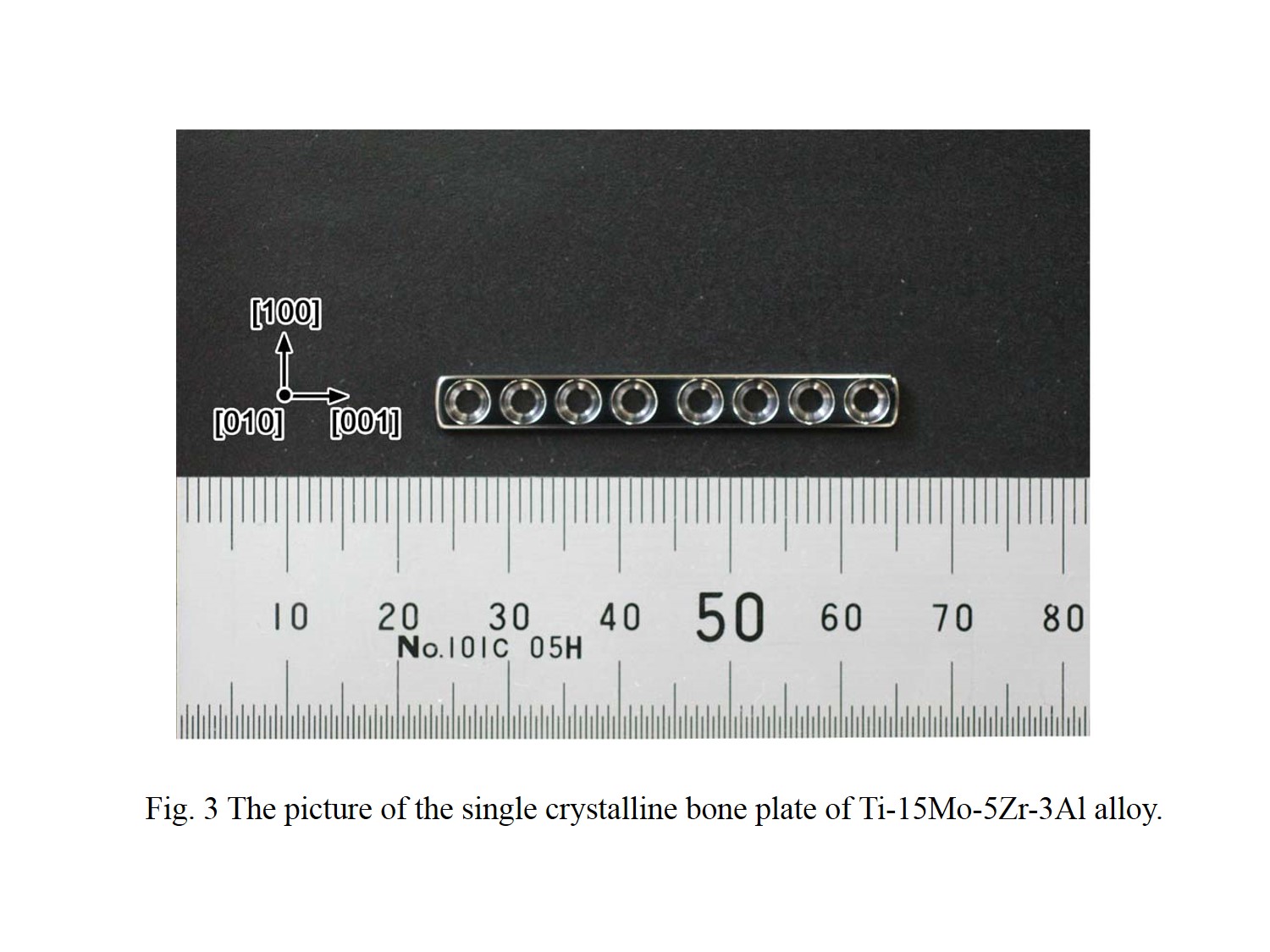

Finally, it was succeeded to be fabricated the bone plate with dimensions of 42 × 5 × 1.5 mm3 and 8 holes for screws could be shaped to be along <100> direction as shown in Fig. 3[7]. The developed single crystalline bone plate with significant low Young’s modulus has a high potential for a clinical use in the orthopedic field.

This work was supported by“Innovative Design and Production Technology Project” under the Strategic Innovation Promotion (SIP) program from the New Energy and Industrial Technology Development Organization (NEDO), by the Ministry of Education, Culture, Sports, Science, Technology (MEXT) of Japan and by the Grants-in-Aid for Scientific Research (S) and Young Scientists (B) from the Japan Society for Promotion of Science (JSPS) and by a resarch grant from the Light Metal Educational Foundation.

References:

[1] M. Geetha, A.K. Singh, R. Asokamani, A.K. Gogia: Prog. Mater. Sci. 54 (2009) 397.

[2] Y. Noyama, T. Miura, T. Ishimoto, T. Itaya, M. Niinomi, T. Nakano: Mater. Trans. 53 (2012) 565.

[3] T. Nakano, K. Kaibara, T. Ishimoto, Y. Tabata, Y. Umakoshi: Bone 51 (2012) 741.

[4] M. Tane, S. Akita, T. Nakano, K. Hagihara, Y. Umakoshi, M. Niinomi, H. Nakajima: Acta Mater. 56 (2008) 2856.

[5] M. Tane, S. Akita, T. Nakano, K. Hagihara, Y. Umakoshi, M. Niinomi, H. Mori, H. Nakajima: Acta Mater. 58 (2010) 6790.

[6] S.H. Lee, M. Todai, M. Tane, K. Hagihara, H. Nakajima, T. Nakano: J. Mech. Behav. Biomed. Mater., 14 (2012) 48.

[7] M. Todai, K. Hagihara, T. Ishimoto, K. Yamamoto, T. Nakano: Tetsu to hagane 101 (2015) 501.