Introduction: Mechanical properties of metallic materials can be controlled by not only alloy design [1] but also constructing appropriate structure [2]. A porous material with adequate pore structure showing appropriate mechanical properties has long been sought as the ideal bone substitute [3], because it exhibits low Young’s modulus and bone ingrowth. However, bone ingrowth into the pores makes the Young’s modulus and the strength increase after implantation. Therefore, it is necessary to implant porous devices showing lower strength than that of living bone. The purpose of this study was to improve the strength of porous implants by filling biodegradable plastic into the pores. In addition, histological observation was carried out for newly formed bone around the implants.

Experimental: The Polyglycolide (PGA) powder and porous Ti (porosity: 60 %) were put in a die and pressed up to 2 MPa at 210-240 ºC by using a high frequency induction heating equipment. Seven-week-old male Sprague Dawley rats (Charles River Japan Inc., Tokyo, Japan) and porous Ti (φ2 × 5 mm) were used in the present study. The specimens were implanted in the tibial metaphysis of the rats. After period of 4 or 12 weeks, histological observation of surrounding tissue was performed.

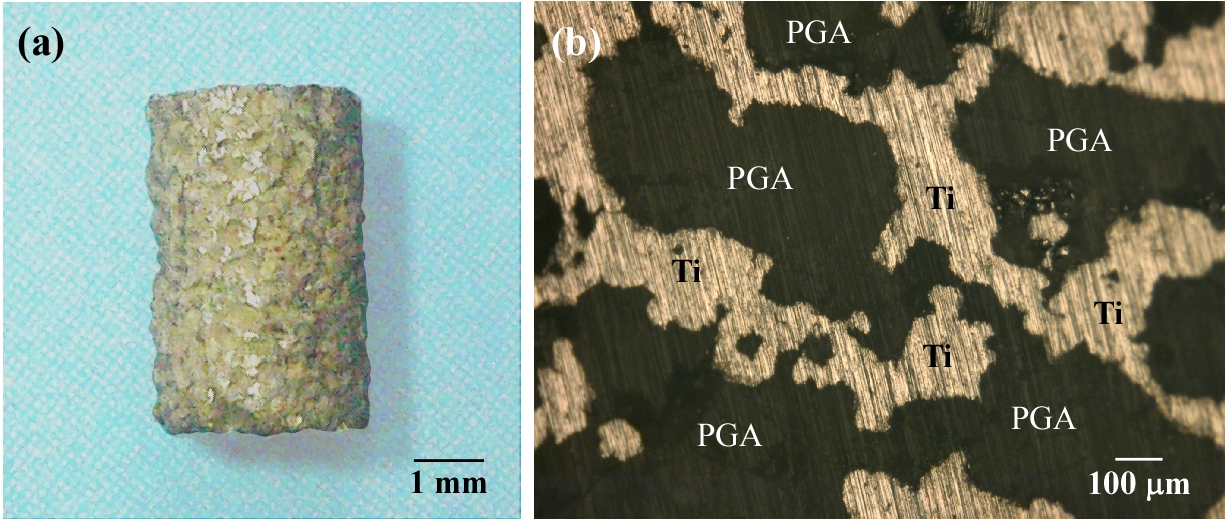

Results and Discussion: Penetration of PGA to the centre could be confirmed (Fig.1). The filling fraction was measured to be 70 %. The porous Ti shows a proof stress of about 40 MPa. The compressive strength drastically increased by filling the pores with PGA, it reached more than 100 MPa. This strength is comparable to that of cortical bone.

Figure 1 – Appearance (a) and cross-section (b) of porous Ti-PGA composite.

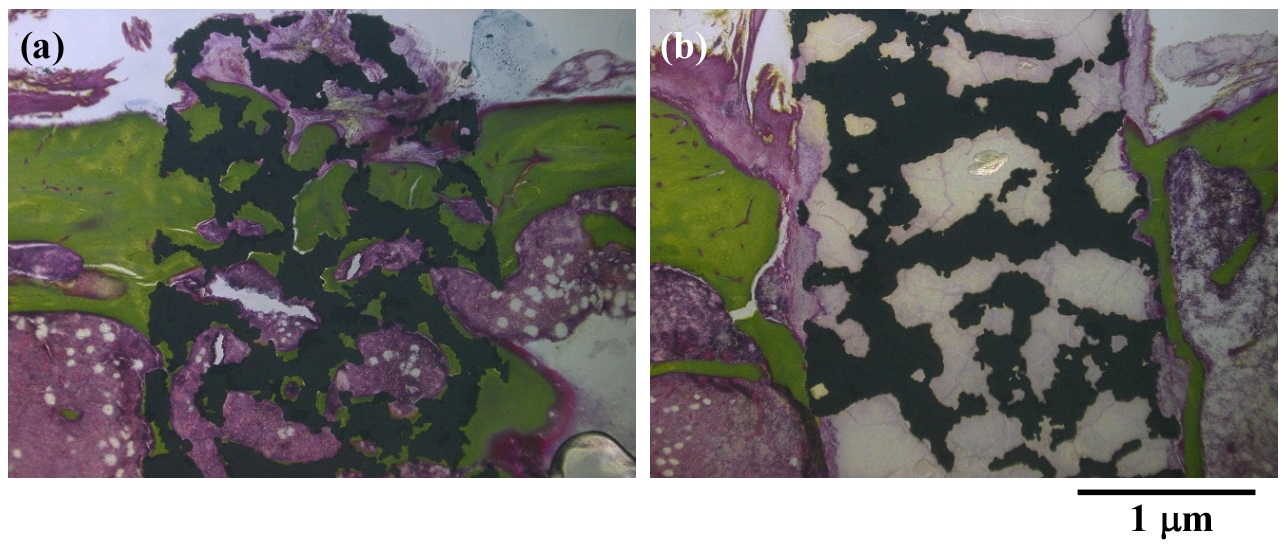

Unfavourable autopsy findings such as suppuration, bleeding, hyperplasia of the connective tissue could not be confirmed. Villanueva Goldner staining allows a clear observation of newly formed bone in relevant parts; it stains the osteoid red and the mineralised bone green (Fig. 2). In the porous Ti, mineralised bone was almost completely conducted to the pores from the cortical bone. Osteoid was also formed in contact portion of cancellous bone or bone marrow. In contrast, nothing was observed in the pores of the Ti-PGA composite. This tendency was also observed in the samples for 4 weeks. PGA makes pH of surrounding region low by decomposition. It is important to control decomposition behaviour of PGA for controlling bone formation in the Ti-PGA composites.

Figure 2 – Light microscopy histological sections in (a) porous Ti and (b) porous Ti-PGA composite after 12 weeks.

Conclusions: 1. Compressive strength of porous Ti was drastically improved by filling the pores with PGA. It was comparable to that of cortical bone.

2. In the porous Ti, mineralised bone was almost completely conducted to the pores from the cortical bone after 12 weeks. Complexed PGA inhibited the bone formation in the pores of porous Ti.It is important to control decomposition behaviour of PGA.

The authors would like to thank the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Grants-in-Aid for Scientific Research (Grant no: 26630355) for providing financial support to this project.

References:

[1] M. Niinomi; M. Nakai; J. Hieda Acta Biomaterialia 2012, 8, 3888.

[2] N. Nomura; T. Kohama; I. H. Oh; S. Hanada; A. Chiba; M. Kanehira; K. Sasaki Mater. Sci. Eng. C 2005, 25, 330.

[3] M. Takemoto; S. Fujibayashi; M. Neo; J. Suzuki; T. Kokubo; T. Nakamura Biomaterials 2005, 30, 6014.