Introduction: Co-Cr alloys are currently used in biomedical applications for artificial heart valves, dental prosthesis, vascular stents and orthopedic fixation plates[1],[2]. L605, a Co-Cr alloy shows excellent mechanical properties, suitable for cardiovascular applications, but the presence of high amounts of Ni, Cr and Co is a health concern. A surface treatment creating a stable surface layer can effectively hinder the release of toxic ions and accommodate substrate deformation. For this reason, an electropolished L605 substrate was modified by oxygen plasma immersion ion implantation (PIII), to improve biocompatibility and increase the corrosion resistance, modifying the chemical composition[3],[4]. The effects of implanted oxygen dose (d) and antenna power (P) were investigated; the characterization of the surface condition was performed by different techniques and the interaction of endothelial cells with the modified surfaces was assessed.

Materials and Methods: L605 flat samples were electropolished and subsequently oxygen implanted with a pulse duration and frequency respectively in the range of 50-100 µs and 10-40 Hz. Effect of antenna power and implanted doses have been investigated, in terms of surface and proliferation of human endothelial cells. X-Ray photoelectric spectroscopy (XPS) and scanning electron microscopy (SEM) were used to assess surface chemistry and morphology. Roughness and surface energy were studied by atomic force microscopy (AFM) and contact angle measurements. Finally, corrosion resistance was investigated by potentiodynamic test in 0,152 M saline solution. Endothelial cell viability was investigated after 1, 3 and 7 days of culture through resazurin tests.

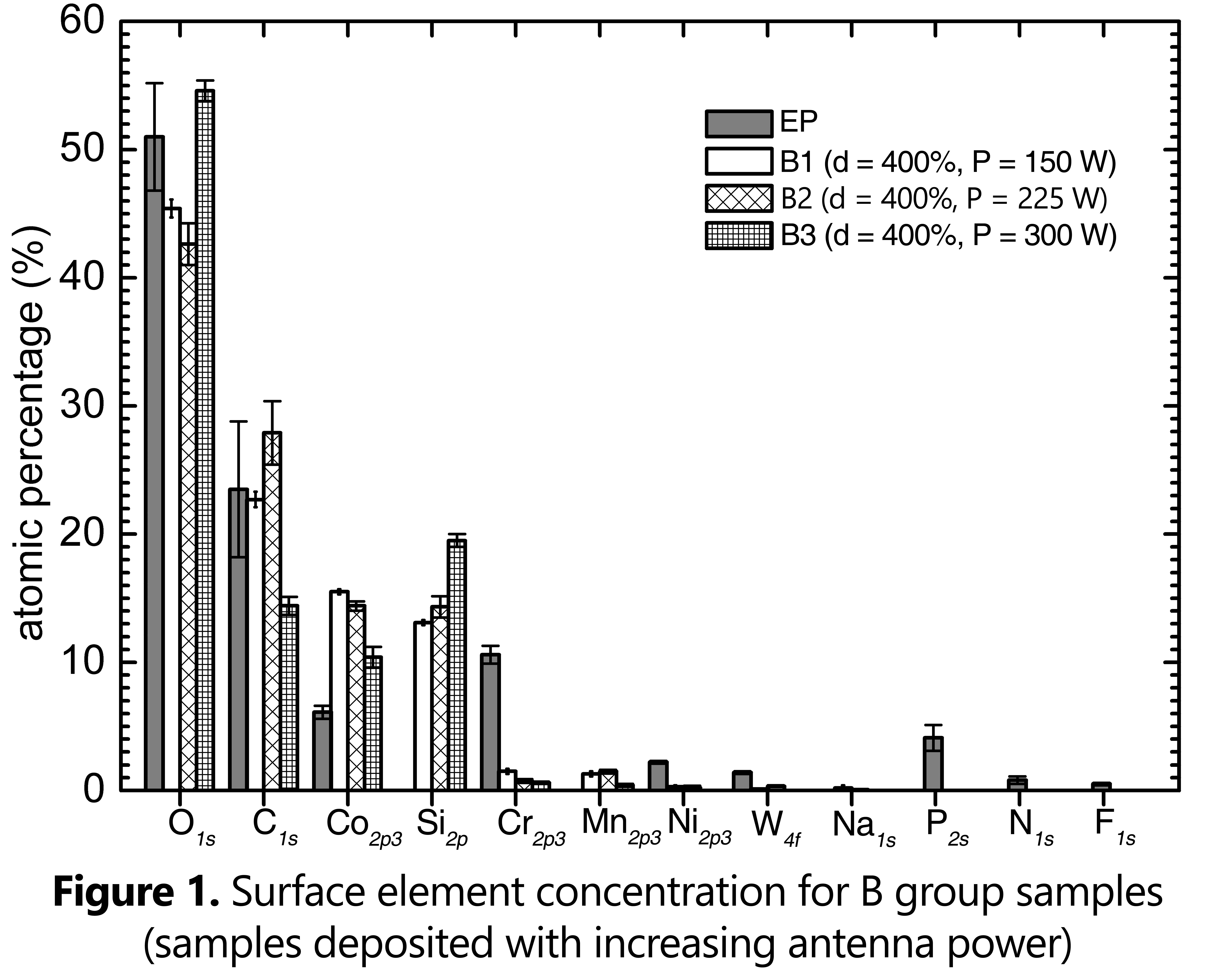

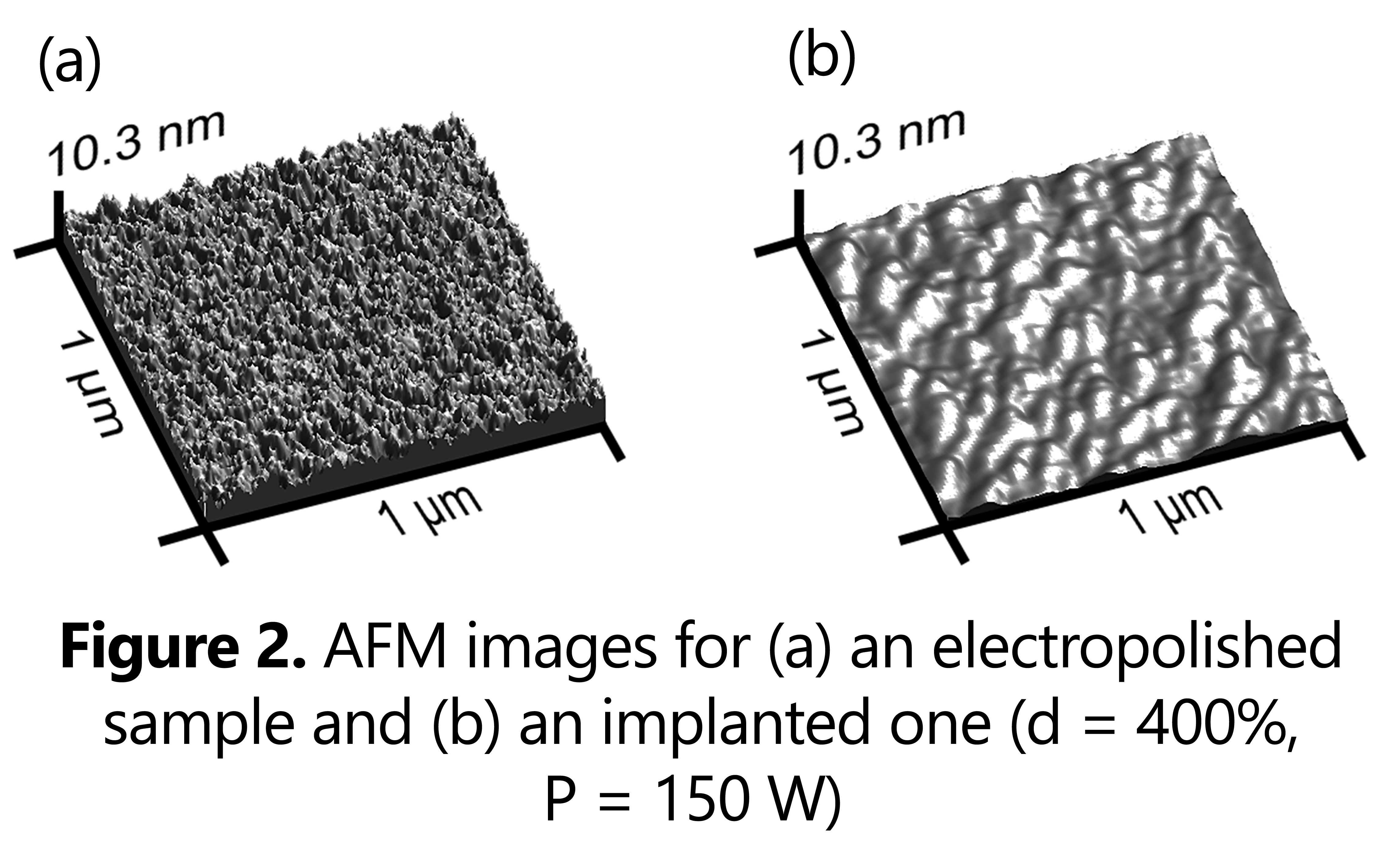

Results and Discussions: After oxygen implantation, the oxidized layer chemical composition is different from the one of the electropolished sample, and it is mainly composed by O and Co (figure 1). The oxygen amount increases for increasing doses (in the range of 17.5 % at. to 54% at.). For increasing antenna power, the oxygen surface amount does not vary in considerable way. XPS analysis attributed O1s peak to the formation of metallic oxides and complex phases including Si. Roughness decreased gradually both with increasing implantation time and with increasing antenna power (figure 2). The implantation process does not affect in a considerable way the surface morphology, as evidenced by SEM micrographs. The potentiodynamic polarization show an increase of Ecorr potential in oxygen implanted samples. Endothelial cell investigations in L605 treated samples show the highest cell viability on A3 condition (d = 400%, P = 300 W) and the lowest on B1 one (d = 400%, P = 150 W).

Conclusions: Oxygen PIII can effectively change the chemical composition and surface energy of the substrate alloy. Increasing both implantation doses and antenna power increase the amount of Co oxide on the surface, improving the corrosion resistance and biological response.

This work was partially funded by NSERC-Canada, FRQ-NT-Quebec and CFI-Canada. VMM was awarded of a doctoral scholarship from Conacyt – National Council of Science and Technology, Mexico. LMA was awarded of an undergraduate scholarship from CNPq - CAPES Foundation and Ministry of Education of Brazil. CP and DM were recipiendaries of the Linkage Grant from Quebec/Italy sub-commission of the Quebec Ministry of Intl Relations.

References:

[1] Mani, G., et al., Coronary stents: A materials perspective. Biomaterials, 2007. 28(9): p. 1689-1710.

[2] Lutz, J., A. Lehmann, and S. Mändl, Nitrogen diffusion in medical CoCrNiW alloys after plasma immersion ion implantation. Surface and Coatings Technology, 2008. 202(15): p. 3747-3753.

[3] Huang, N., et al., Surface modification of biomaterials by plasma immersion ion implantation. Surface and Coatings Technology, 2004. 186(1–2): p. 218-226.

[4] Lieberman, M., Model of plasma immersion ion implantation. Journal of Applied Physics, 1989. 66(7): p. 2926-2931.