Introduction: Alumina (Al2O3) film has high wear and corrosion resistance, chemical inertness, high electrical resistivity, and thermal conductivity, etc[1]. Additionally, plasma sputtering alumina film has good blood compatibility and it has been promising for artificial heart valve development[2]. It is well known that alumina film is one of good materials of biocompatibility and often used as medical devices, however, plasma processing including sputtering technique is limited to flat substrates. On the other hands, atomic layer deposition (ALD) technique has been proposed for a reliable and cost-effective conformal deposition on high aspect ratio three-dimensional nanostructures. It has an advantage in atomic layer control and conformality deposition using sequential, self-limiting surface reactions[3],[4]. Recent trials on ALD alumina film has indicated promise for hasten cell growth applications. The cellular response was controlled by concentration of –OH group on alumina surface without cytotoxicity[5]. Therefore, ALD technique is available with a variety of compositions as surface modification of medical devices. In this study, in order to investigate biological response of interaction in long term, we observed thrombus formation of blood compatibility at ALD-alumina film surface which was deposited on segmented polyurethane (SPU) micro fiber scaffold sheet, in in-vivo test.

Materials and Methods: SPU micro fiber scaffold was fabricated by electronspinning method. SPU (Mn = 80,000, Mw = 160,000) dissolved in mixture solution of Tetrahydrofuran / N N-dimethyl formamide (8:2). The SPU solution (14.5 wt%) was drawn at 12.5 kV, and the SPU scaffold with a fiber diameter was kept around 1.0 μm. The thickness and diameter of the scaffold sheet was 500 μm and φ10 mm, respectively. After the fabrication of the SPU scaffold sheet, ALD technique utilizes sequential, self-limiting surface reactions of chemical species to deposit alumina film on the scaffold sheet by using sequential exposures of trimethylaluminum (TMA) and H2O in the ALD system manufactured by ULVAC,Inc. After the film deposition, the ALD alumina scaffold sheet was implanted at partial aorta descendens of a goat for 42 days in in-vivo test.

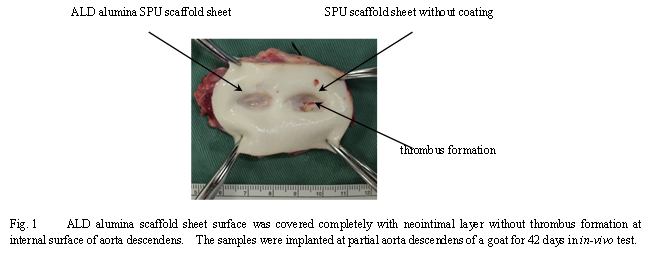

Results and Discussion: For alumina film coating, Al2p peak was observed on the SPU scaffold sheet surface by X-ray photoelectron spectrometer (XPS) with Mg Kα radiation. After the in-vivo test, the blood surface interaction of the alumina scaffold sheet was investigated by hematoxylin-eosin (HE) stain method. In the in-vivo test, the ALD alumina scaffold sheet surface was covered completely with neointimal layer. On the other hand, the thrombus formation was significantly observed at surface of the SPU scaffold sheet without ALD alumina coating. For blood compatibility, blood-contacting devices require that stable thrombus formation without inflammatory reaction and neointimal formation of thrombus layer at blood contacting surface. It was expected that the ALD alumina film coating inhibits thrombus formation accompanied by inflammatory reaction and induces neointimal layer formation at the blood contacting surface.

Conclusion: ALD alumina film surfaces had no thrombus formation as an inflammatory reaction and good blood compatibility. This coating technique is expected to emerge as a potential technique for surface modification of practical medical devices.

The authors would like to thank Kazuhiro Honda of ULVAC, Inc. for preparing ALD alumina films.

References:

[1] Q. Chen, G. Thouas, Biomaterials: A Basic Introduction, CRC Press, 2014.

[2] T. Yuhta et al., Journal of Biomedical Materials Research, 28, 217-224, 1994.

[3] S. M. George, Chemical Reviews, 110, 111-131, 2010.

[4] R. L. Puurunen, Journal of Applied Physics, 97, 121301, 2005.

[5] D. S. Finch et al., Journal of Biomedical Materials Research Part A, 87A, 100 - 106, 2008.