Introduction: Coatings are known to be one of the best suited strategies to tailor interactions between medical surfaces and the surrounding cells and tissues. They offer the possibility to modify the surface properties with functionalization and film deposition without affecting the bulk mechanical properties of a material. With the increased role of nanotechnology in the biomaterial field and the experimental evidence gathered in recent years, the need to precisely engineer film/substrate interfaces has become increasingly acknowledged within the biomedical community [1],[2]. Interfaces play a major role on coatings’ adhesion and stability and can impact several other properties. This work presents applications of interface engineering for stability and adhesion improvement, with a focus on two particular applications: bioactive and protective coatings for cardiovascular stents and antibacterial coatings for hospital settings.

Methods: The substrate/nanocoating systems investigated in this work were: 1) 316L stainless steel (SS316L) /fluorocarbon (CFx) [3], 2) CFx/biomolecules [4] and 3) SS316L/Diamond-like carbon (DLC) [5]. All interface modifications and coating deposition were performed using low-pressure plasma-based processes. Complementary characterization techniques have been used to assess surface modifications, including X-Ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM) and scanning electron microscopy (SEM). The systems stability was investigated through electrochemical (potentiodynamic and galvanostatic) and dynamic flow tests. The adhesion of nanocoatings was also studied using small punch (deformation) and pull-off tests.

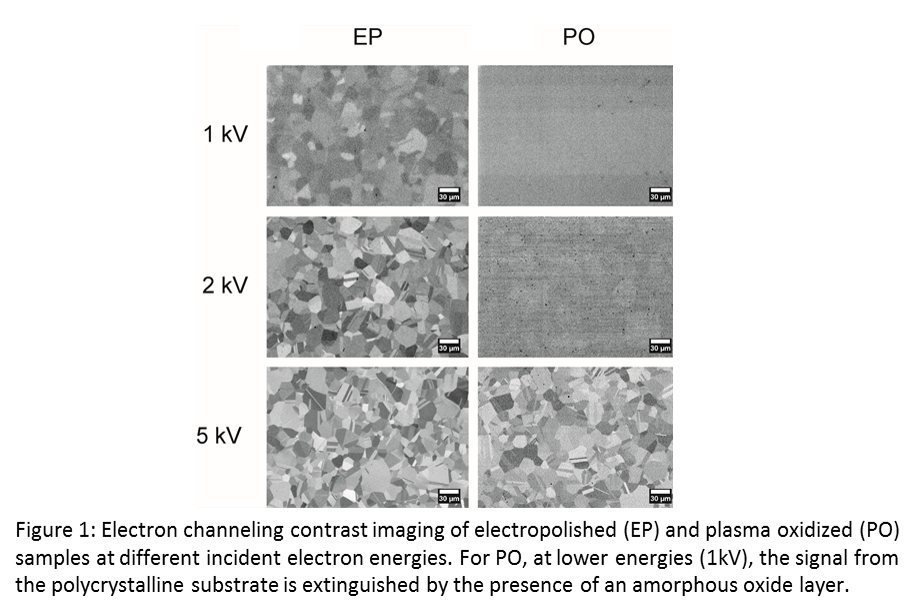

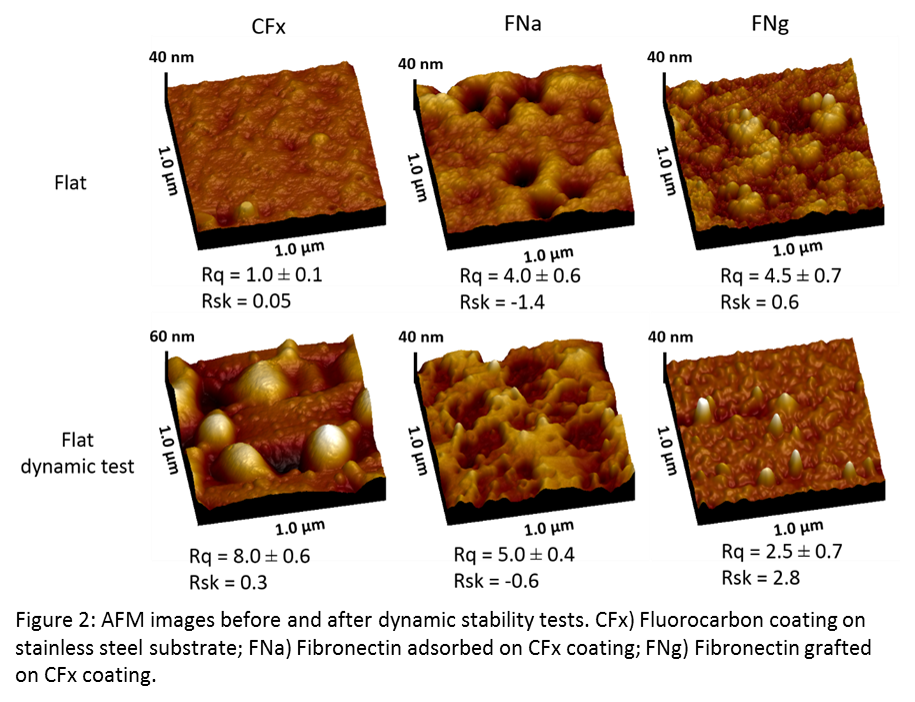

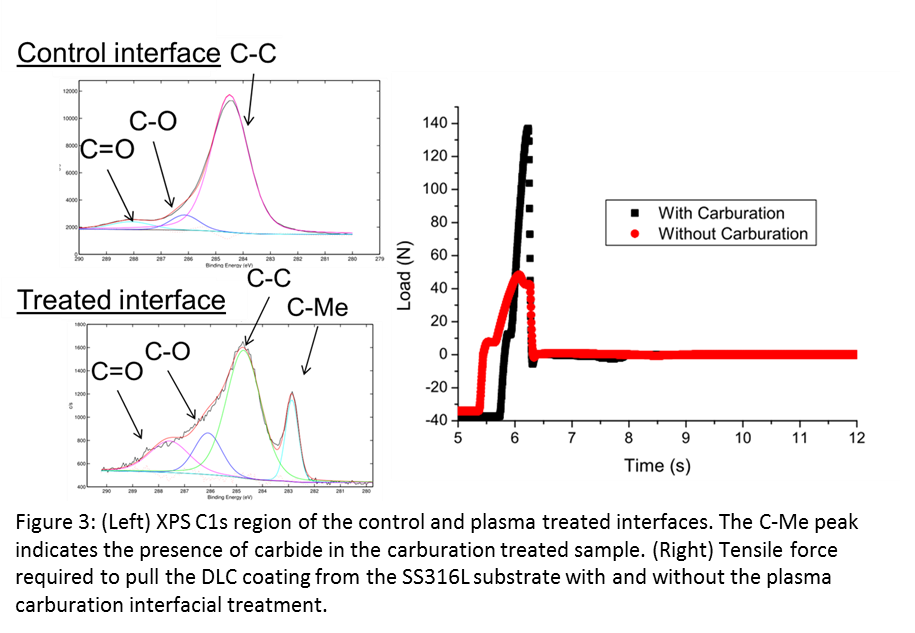

Results and Discussion: The stability of the 316LSS/CFx system was shown to be highly correlated with the crystallinity and thickness of the interfacial oxide layer. A plasma oxidation process was used to produce a thicker, amorphous oxide layer at the SS316L/CFx interface (Figure 1). The corrosion rate was consequently reduced 11-fold compared with the control sample. In the CFx/biomolecule system, different fibronectin immobilization strategies were assessed for stability. According to AFM analysis, skewness (Rsk) values suggested a more homogenous surface in fibronectin grafted (FNg) rather than adsorbed (FNa) (Figure 2). After dynamic tests under flow, the roughness (Rq) value for FNa was similar, while it decreased for FNg, suggesting changes in conformation of the protein leading to a denser coating. For the SS316L/DLC system, the presence of an interfacial carbidic layer was demonstrated to increase the adhesion of DLC on stainless steel, with an observed increase in bonding strength and resistance to delamination (Figure 3). The formation of the thin interfacial carbide layer was achieved using implantation of carbon ions by plasma.

Conclusions: Plasma-based surface modifications can be successfully exploited to engineer substrate/nanocoating interfaces and improve the stability and adhesion of several biomaterials. They represents an interesting, polyvalent and powerful tool for tuning the surface and the interface properties for coatings and surfaces.

This work was partially funded by NSERC-Canada, FRQ-NT-Québec, CFI-Canada, the Canadian Space Agency, MRI-Québec and with the support of Wallonie-Bruxelles International (WBI); MC was awarded a prestigious NSERC Vanier Scholarship; VMM was awarded a doctoral scholarship from CONACYT – National Council of Science and Technology, Mexico; CP and DM were recipients of the Linkage Grant from Quebec/Italy sub-commission of the Quebec Ministry of Intl Relations

References:

[1] Lewis, F., et al. (2011) Influence of the 316 L Stainless Steel Interface on the Stability and Barrier Properties of Plasma Fluorocarbon Films. ACS Appl. Mater. Interfaces 3, 2323-2331.

[2] Hauert, R., et al. (2012) Analysis of the in-vivo failure of the adhesive interlayer for a DLC coated articulating metatarsophalangeal joint. 25, 34-39

[3] Cloutier, M., et al. (2012) On the Interface between Plasma Fluorocarbon Films and 316L Stainless Steel Substrates for Advanced Coated Stents. 409, 117-122.

[4] Montaño-Machado, V., et al. (2015) On the potential for fibronectin/phosphorylcholine coatings on PTFE substrates to jointly modulate endothelial cell adhesion and hemocompatibility properties. 5, e979679.

[5] Cloutier, M., et al. (2014) On the long term antibacterial features of silver-doped diamondlike carbon coatings deposited via a hybrid plasma process. Biointerphases 9, 029013.