Introduction: This project aims to create a tissue-engineering scaffold with bi-phasic Janus-type structural and biological properties. The key goal was to create a fiber scaffold with biphasic properties on each side. In this project we aim to explore ways to control Janus-type biphasic behavior as it pertains to fiber alignment, diameter, mechanical properties and cell adhesion properties of the scaffold.

Materials: The polymers and proteins utilized were polycaprolactone (PCL) and gelatin, respectively. Seven percent solutions of differing PCL/gelatin ratios were dissolved in Hexafluoro-2-propanol (HFIP) (Pure PCL, 3:1, 2:1, 1:1, 1:2, 1:3, and Pure Gelatin).

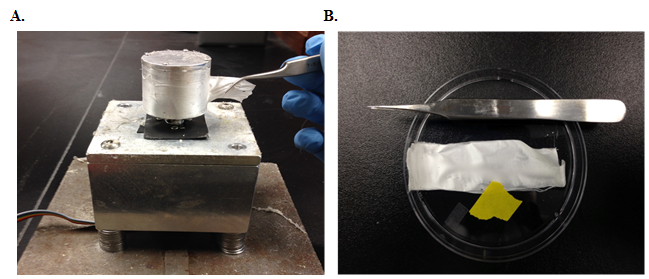

Methods: A double reservoir with orifices towards the bottom of each reservoir was used to extrude Janus nanofiber scaffolds, with one side having pure PCL composition and the other containing the aforementioned blends of PCL/gelatin. A commercially available motor was used to spin the reservoir at various RPMs (20k, 25k, and 30k) and the extruded fibers were collected. Alignment and fiber diameter of the nanofiber scaffolds were assessed via analysis of Scanning Electron Microscope (SEM) images of the fibers. The physical and chemical presence of Janus-type biphasic properties was assessed using Fourier Transform Infrared (FTIR) Spectroscopy.

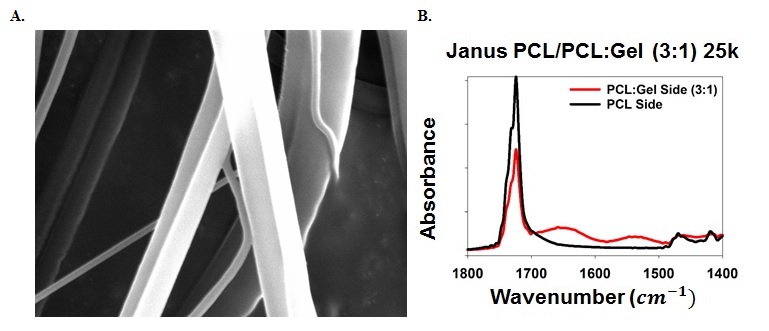

Results: Our results indicate a direct correlation between higher RPMs and creating fibers with increased alignment and decreased fiber diameter. Additionally, the presence of bi-phasic Janus fibers has been confirmed both using SEM imaging and surface property measurements with Fourier Transform Infrared Spectroscopy.

Figure 2a displays a SEM image of a representative scaffold showing biphasic Janus-characteristics at the individual nanofiber level. Figure 2b displays a representative FTIR Spectrogaph of a fiber scaffold that was Pure PCL on one side and a ratio of PCL:Gelatin (3:1) on the other side. Both sides display a prominent absorbance peak at ~1750cm-1 which reflects the carbonyl bond of PCL. However the absorbance peak is much less in magnitude on the biohybrid side due to the incorporation of gelatin. The biohybrid side displays additional absorbance bands at ~1650cm-1 and 1545cm^-1 which reflect the amide 1 and amide 2 bonds of gelatin. This result documents the presence of biphasic Janus character at the macro-level in the scaffold constructs.

Discussion: Our results have successfully demonstrated the fabrication of scaffolds with Janus-type behavior at the macro and single fiber levels. We did discover that Janus character was reduced as fabrication RPM increased, and we hope to explore this phenomenon in future studies. Additionally, the results on alignment and diameter were in agreement with studies published on singlephase jet-spun nanofibers[1].

Conclusion: This study highlights the potential to create scaffolds that provide different properties on either side. With these biphasic Janus type fibers, the mechanical and chemical make up of the constructs can potentially be tuned to facilitate numberous tissue engineering applications. Future studies will include exploring the relationship between fabrication parameters and hydrophobicity of the two surfaces of these constructs and exploring the viability of the scaffolds with living cells.

State Undergraduate Research Fellowship; Institute for Nanoscience and Engineering, University of Arkansas; Prof. Xianghong Qian, University of Arkansas

References:

[1] Badrossamay MR, Balachandran K, Capulli AK, Golecki HM, Agarwal A, Goss JA, et al. Engineering hybrid polymer-protein super-aligned nanofibers via rotary jet spinning. Biomaterials. 2014;35:3188-97.