Introduction: Coaxially electrospun polymeric nanofibers are promising carriers for versatile bio-active agents, growth factors and drugs, allowing for their control release. On the other hand shape memory polyurethanes have excellent thermal shape memory effect and demonstrate high biocompatibility. Thus recently core-shell nanofibers based on this kind of polymers have gained much attention in various biomedical applications like cardiovascular stents. In this study preliminary investigation of electrospun fibers made of polyurethane and polyurethane/gelatine with encapsulated microspheres towards drug release and shape memory was performed.

Materials and Methods: Polyurethane PCL/PLLA with shape memory based on PCL and PLLA was synthesized by polymerization in our laboratory. PCL-PEO nanoparticles ere prepared according to the protocol: 10mg of each copolymer was added to 90% THF/water mixtures and left shaken overnight till full dissolution copolymers was achieved. Then solutions were added drop-by-drop to water under vigorous stirring. Finally the solutions were dialyzed against water.

In our experiments, for comparison, core –shell fibers with PCL/PLLA; PCL/PLLA:Gelatin [90:10], PCL/PLLA:Gelatin [80:20] in HFP as a shell and microspheres in water as a core, were prepared using the co-axial electrospinning.

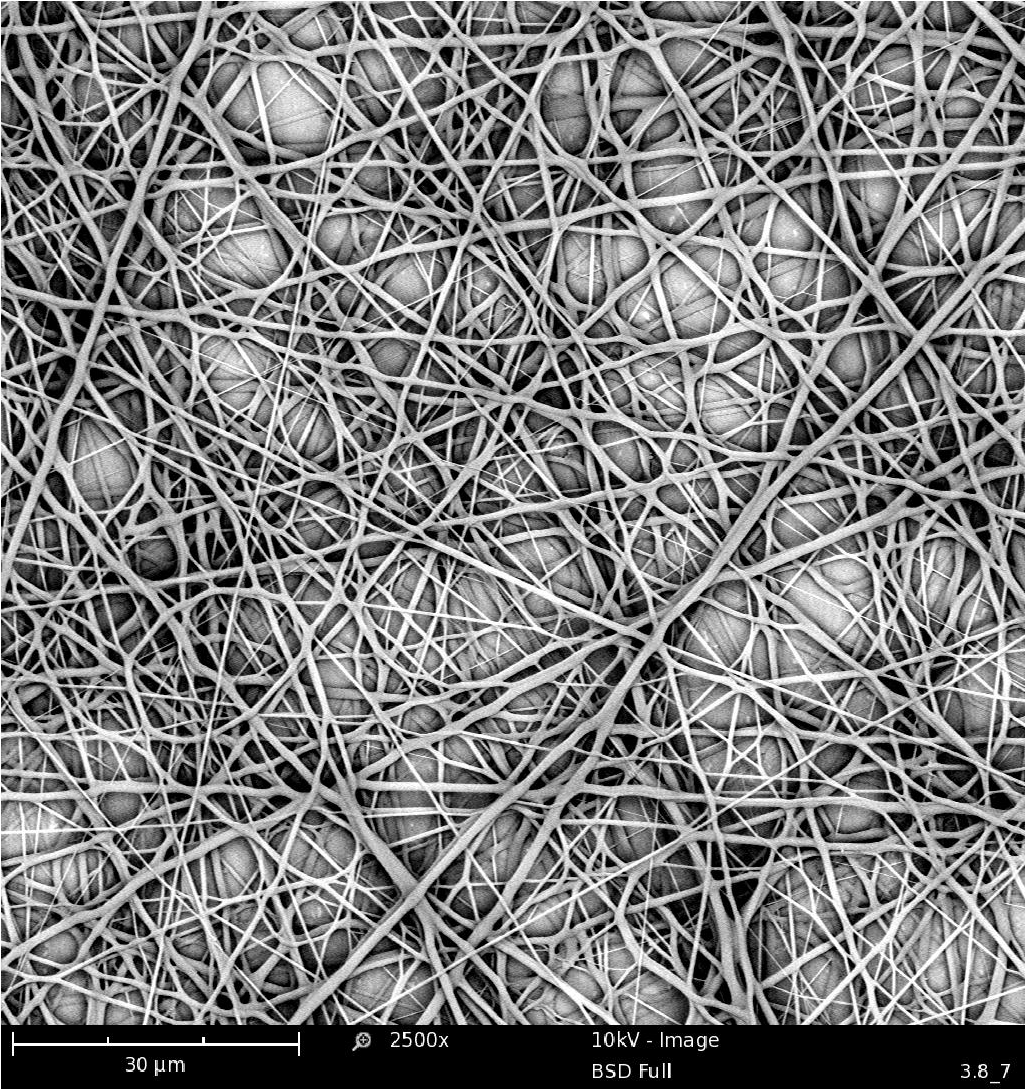

Results and Discussion: Electrospun uniform and bead free fibrous structures were successfully fabricated using co-axial electrospinning. SEM micrographs (Fig.1) of electrospun mesh revealed porous, beadless, fibrous topography. TEM investigation confirmed core-shell character of obtained fibers. Contact angle measurements data supported the fact that the incorporation of gelatin made meshes more hydrophillic compared fibers with pure polyurethane shell, thus more sufficient for biomedical applications. Release studies showed potential of use of this types of fibers for encapsulation of the drug loaded microspheres.

Conclusions: Our studies suggest the potential application of co-axially electrospun PCL/PLLA polyurethane fibrous carriers with encapsulated drug loaded microspheres as a suitable substrate for target tissue engineering and indicate co-axial electrospinning technique as a promising method for fabrication of polyurethane fibers with improved functionality.

The authors would like to thank the National Centre for Research and Development (Grant no: LIDER/037/673/L-4/12/NCBR/2013) for providing financial support to this project.