Introduction: Poly(glycerol sebacate) [PGS], a biopolymer, has shown some promising potentials as an implant in human body due to its predictable biodegradable properties[1],[2]. However, the preparation of PGS is very time-consuming and the reproducibility is always an issue[3]. Thus, alternative synthetic procedures are required to large scale controllable production of PGS. The main aim of this work is to reproducibly synthesise the PGS with controllable mechanical and thermal properties by varying levels of crosslinking using a scalable, economic and fast approach.

Materials and Methods: Stoichiometric amounts of glycerol and sebacic acid were polymerized into prepolymers using microwave heating (MH) methods. For the cross-linking, the prepolymers were further cured in the vacuum oven at 120 ˚C for 24 to 48 hours.

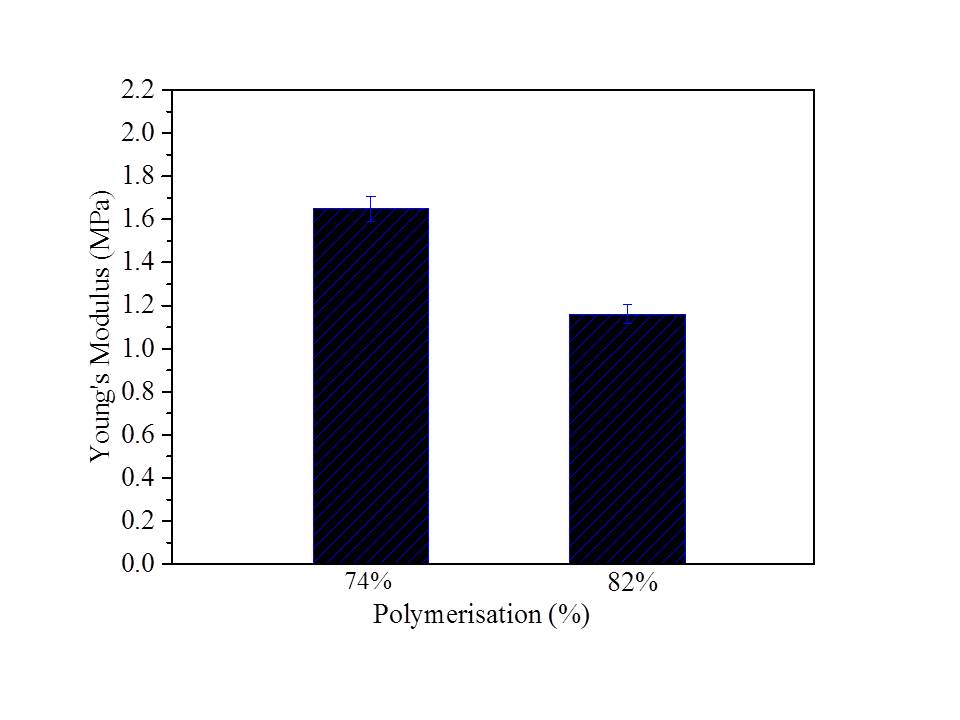

Results and Discussion: Consistent with previous studies, a viscous polymer is obtained upon ~74% polymerization, compared to a sticky elastomer for ~82% polymerization[3]. FTIR spectra of prepolymers with different degree of polymerisation prepared by MH show characteristic carbonyl stretching for PGS (νC=O) at 1740 cm-1, confirming polyesterification spectroscopically. By controlling the level of polymerization, PGS samples performed different mechanical properties which are crucial for biomedical applications. For example, prepared PGSMH (82%) showed lower Young’s modulus than PGSMH (74%), probably due to the level of cross-linking.

Figure: (1) FTIR spectra of PGS samples (prepolymers), with ~74-82% of polymerization, prepared by microwave heating methods. (2) Young’s modulus of these prepolymer samples after a short curing period in vacuum oven at 120 ˚C.

Conclusions: Therefore I have successfully prepared PGS with controllable cross-linking by MH method. Interestingly, this method was dramatically reduced the reaction time compared with the reported literature[1],[3], but it remained the same physical properties of the polymer. The tunable mechanical properties and cross-linking levels of PGS can be further applied in biomedical area, such as bone implants.

References:

[1] Y. Wang, G. Ameer, B. Sheppard, and R. Langer, “A tough biodegradable elastomer,” Nat. Biotechnol., vol. 20, no. June, 2002.

[2] R. Rai, M. Tallawi, A. Grigore, and A. R. Boccaccini, “Synthesis, properties and biomedical applications of poly(glycerol sebacate) (PGS): A review,” Prog. Polym. Sci., vol. 37, no. 8, pp. 1051–1078, Aug. 2012.

[3] X. Li, A. T.L. Hong, N. Naskar, and H.J. Chung, “Criteria for Quick and Consistent Synthesis of Poly(glycerol sebacate) for Tailored Mechanical Properties.,” Biomacromolecules, vol. 16, no. 5, pp. 1525–33, May 2015.